Northrop Grumman

Continually involved since 2003.

Northrop Grumman is one of the largest aerospace and defense companies.

Highlight of few projects:

- Developed methodology and programmed very complex and professional PDF reports using XML/XSL/FOP.

- Completed the development and deployment of Pro/E migration from Pro/PDM to Teamcenter and business processes related to release of CAD data. Analyzed Pro/E integration performance and worked to improve it.

- Worked on migration of PLM data for FA/18 from legacy mainframe applications to Teamcenter.

- Interfaces between PLM system and various other systems for different Programs.

- Upgraded CF2.0/ADS2.0 to Teamcenter 3.1/ADS3.1. The strategy/tools supplied by software vendor were too slow for a large installation. Developed own strategy/tools.

- Working in the team to continually develop and enhance IES, a corporate wide PLM system, built upon Teamcenter Enterprise.

- Implemented the process and tools to syncronize the configuration setup (rules, conditions, roles, lifecycles, etc.) across mutilple Teamcenter environments (production, test, integration, training, etc.)

An International Healthcare Company

InfoTechnik has implemented many PLM projects since 2002, at this global diversified healthcare company making products in medical devices, pharmaceuticals and biotechnology fields.

Highlight of few projects:

- Provided PLM consulting support in requirements analysis and system design.

- Developed a tool to ease the manipulation of the Bill of Materials. The out of the box tool was too cumbersome to manipulate large complex BOMs.

- Upgraded the PLM system from Metaphase 3.2 to Teamcenter 5.0 in 2007. This was a daunting task, as many intermediate versions of software had to be skipped. The customer put their trust in InfoTechnik to accomplish this difficult task. Successfully completed the project in schedule and on a fixed price fee.

- Won a contract to deliver a tool to load parts and document data from all manufacturing plants worldwide into the corporate PLM system. This tool has been used in the last two years extensively.

- Implemented the process to manage change in bioscience facilities. The change management process is very complex in medical industry, requiring approvals from FDA and regulatory agencies from other nations, complete documentation and history. Three persons from InfoTechnik worked with the customer for a year in all aspects of the project, from requirements gathering/analysis, system design, process definition, programming, reports, testing, integration and deployment.

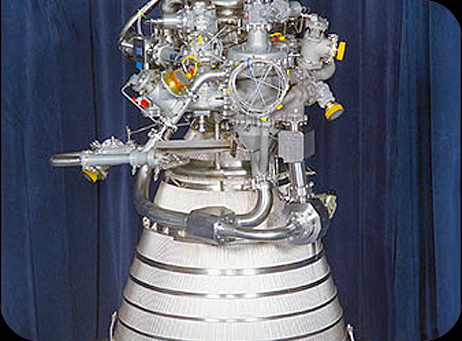

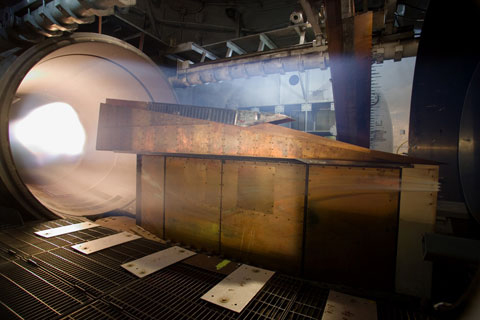

Pratt & Whitney Rocketdyne

Rocketdyne is world famous for making the rocket engines for Space Shuttle and for many other rockets. InfoTechnik has implemented many PLM projects since 1995.

Highlight of few projects:

- Developed the module in Teamcenter to manage effectivity, i.e. managing which part goes into specific serial number of end items, in this case rocket engines. Managing effectivity in aerospace is quite a challenge.

- Developed the interface to transfer the Bill of Materials with effectivity information to the ERP system. This was a very complex and challenging problem, affecting many functions and processes in the company, requiring their acceptance of changes. Delivered an elegant and simple solution in eight months, working flawlessly for many years.

- Designed and built the interface between PLM system and Pro/Engineer.

- Transfer of BOM from CAD applications to PLM system.

- Upgraded the PLM system from CF2.0 to Teamcenter 4.0 in 2006. The resources provided by software vendor could not perform this task. After six months, Rocketdyne gave the project to InfoTechnik.

- Upgraded the PLM system to Teamcenter Enterprise 2005SR1 in 2007.

Seagate

Seagate Technology is a leading storage devices manufacturer. Seagate’s disk drives are used in enterprise computing, mobile devices, desktop, consumer electronics. InfoTechnik has implemented many PLM projects at Seagate since 1995.

Highlight of few projects:

- Provided PLM consulting support in requirements analysis and system design when Seagate started with the first implementation of PDM in 1995.

- Developed integrations to manage MCAD and ECAD data.

- Implemented a distributed PLM system to link four design centers and factories all over the globe to share engineering and manufacturing information.

- Migrated parts, documents and BOM data from Oracle ERP system to PLM system.

- On spinoff of Quantum from Seagate, removed the data for Quantum products from Seagate`s PLM system and loaded it in Quantum`s Teamcenter. Fixed Price Contract.

- Migrated PLM data from Quantum`s Teamcenter system to an Agile PLM system. Fixed Price Contract.

Mattel

Mattel Inc. is the leading toy manufacturer. Mattel’s toy brands include Barbie Dolls, Fisher Price, Hot Wheels, Matchbox, etc. InfoTechnik has implemented many PLM projects at Mattel from 1995 to 2000.

Highlight of few projects:

- Implemented the first global distributed PLM system linking the design centers in US and factories in Mexico and Asia. The PLM system managed the engineering, tooling, packaging, and manufacturing information about Mattel`s diverse product line. Provided PLM consulting support in requirements analysis and system design when Seagate started with the first implementation of PDM in 1995.

- To reduce cost and improve engineering processes, migrated the BOM system from IBM mainframe to PLM system. Completed the total project, from requirements, design, development, interfaces to MRP system, migration of data and training in one year at less than one tenth the price quoted by major consulting houses.

- Developed the module to manage global brands, that is, organizing the hundreds of products according to global branding scheme to provide critical information to marketing and sales.